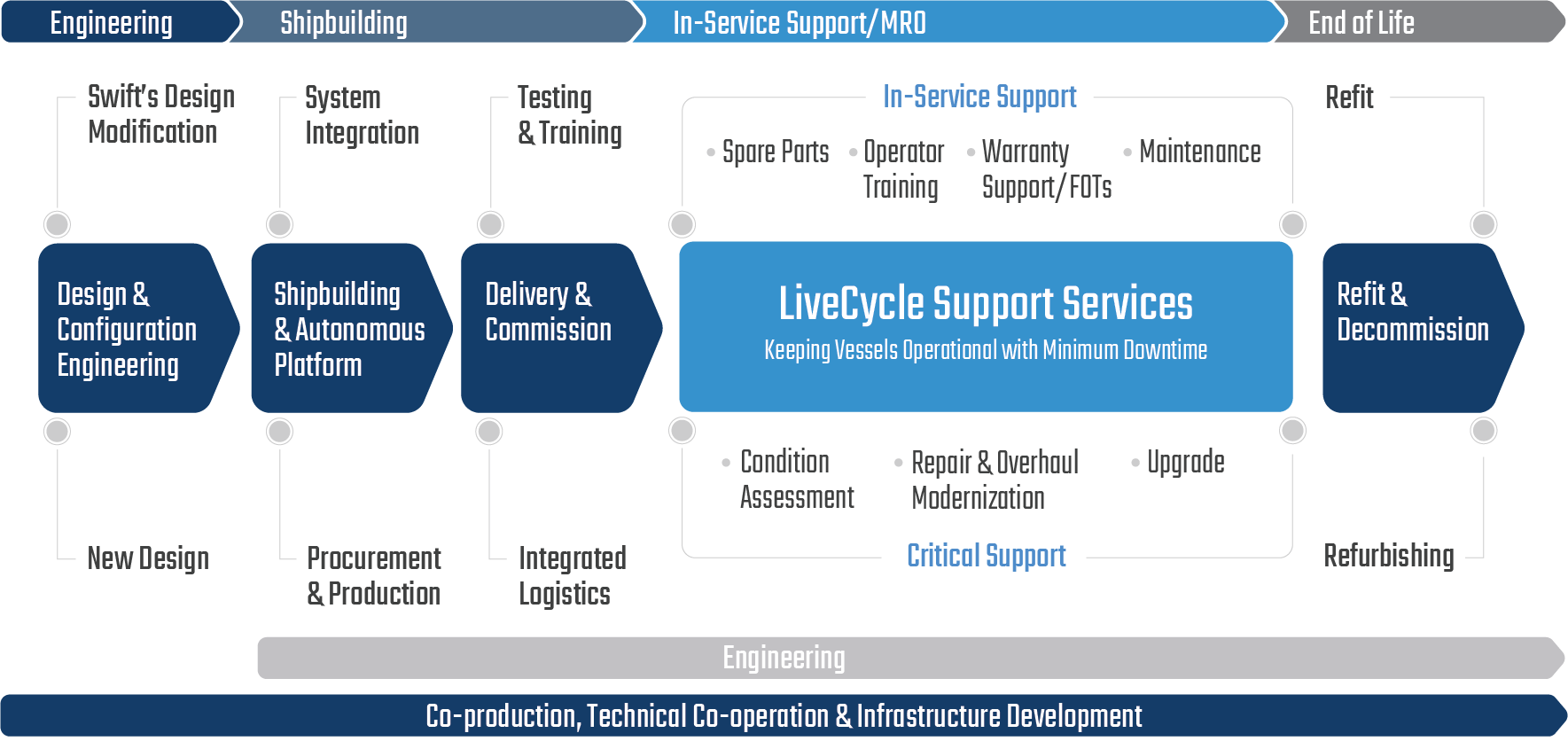

Vessel's Life Cycle Solutions

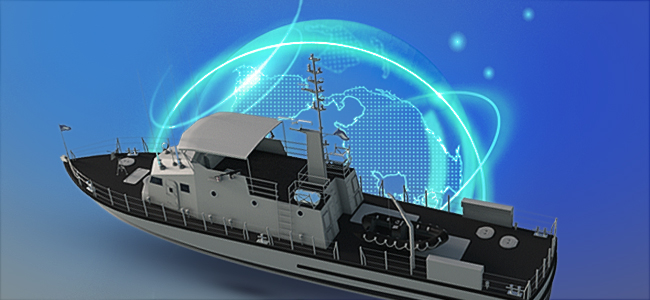

Since our establishment in 1942, Swiftships has been recognized for providing innovative and effective solutions, offering end-to-end shipbuilding, testing, and delivery services for new vessels, complemented by hands-on training and vessel lifecycle sustainment support. We are trusted to support Defense Missions and Commercial Operations, and our client base includes Navies and Maritime customers from 53 countries. We predominantly serve the Department of Defense, Navies, and Army operations, either as a prime contractor or subcontractor.

Unique to Swiftships, we own over 120 Military and Commercial purpose vessel designs, and we are renowned in the market for our ships remaining in service for over 45 years. We effectively leverage our proven hulls by modifying them according to client specifications, militarizing commercial platforms, or using our proven hulls as a platform for unmanned, semi-manned, or remote-controlled vessels.

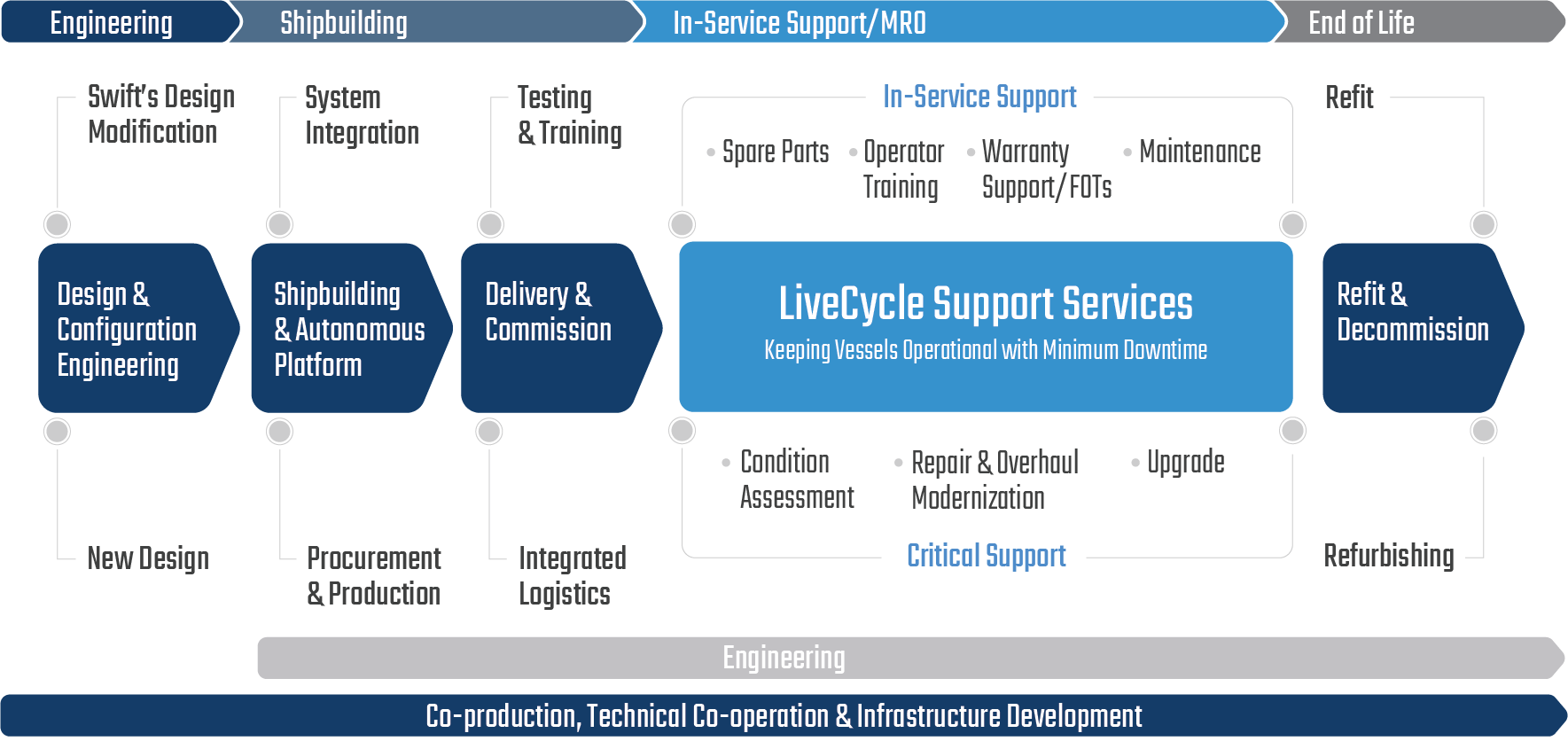

With experience in all aspects of engineering and shipbuilding, along with the ability to provide maintenance, repair, and overhaul (MRO) services for different vessel types, Swiftships stands as a comprehensive solution provider for our clients.

Business Segments

We operate our business through five main divisions: Engineering, Shipbuilding, System Integration & Autonomy, MRO, Co-production and Specialized Professional Services.

Swiftships has in-house design and engineering capability for new-build, MRO or vessel’s conversion/refit projects. This allows us to offer full package solutions to our clients, and efficiently resolve any change/modification requirements. Our engineering teams are capable of all design processes – from basic to functional and development design, technical assistance to production and change management.

We possess over 100 of proprietary hulls’ designs that come with test data packages, and we are successful in modifying tested hulls for client specific requirements. Swiftships platforms are known in the market for their clear contours, precise lines and pure surfaces. This DNA makes our unique designs increasingly innovative, efficient, safe, durable and Swift.

Subsegments and Services:

Shipbuilding has been Swiftships core business since establishment, with over 1000 hulls constructed for our customers worldwide. We are trusted by navies and commercial clients to provide complete solution – from prototype design and construction, to complete ship systems, logistics and operator training. Swiftships builds vessels from aluminum, steel, or a combination of both, and our portfolio ranges from corvettes, fast patrol boats and amphibious vessels, to commercial platforms such as fast supply and maintenance vessels.

We take pride for pioneering in autonomous vessels market and being upfront with our expertise and technology. Swiftships’ name has been central to conversations around Unmanned Autonomous Vessels (UAVs) since the US Navy’s 2018 selection of the Swiftships’ Riley Claire – a 175ft fast supply vessel (FSV) for transformation into a Large Unmanned Surface Vessel (LUSV), the first of its kind. Since then, we have revealed our own design SUSV Challenger, and are constructing MUSVs for the US Navy.

Case Studies:

Subsegments and Services:

Whether built by Swiftships or not, we help to maintain vessels operational and extend their life of service. We have decades of experience providing all aspects of Service Life Extension Programs (SLEP), Maintenance, Repair and Overhaul (MRO) and Refit/Ship Modernization services for various types and sizes of ships. We are recognized as a service provider by the US Navy, NAVSEA and foreign allies Navies helping them in managing their fleets.

Our programs of record include major SLEP for LCU 2000 vessels for the U.S. Army, and Iraq Fleet Management and Continuous Lifecycle Support (CLS) for entire Iraqi Navy (IqN). You can download case studies, or visit relevant pages to learn more.

Case Studies:

Subsegments and Services:

For economic and strategic reasons, our clients may want to have vessels constructed at their locations. Swiftships recognized these needs, and became a U.S. based maritime company specializing in global co-production programs. Our localization programs support governments in increasing their indigenous industrial base, creating local employment and bringing technology and know-how to their countries for long-term benefit.

We have extensive experience working with international clients, and we are experienced with ITAR (International Traffic in Arms Regulations) requirements and processes for Transfer of Technology (ToT), Transfer of Production (ToP), Program Management (PM) and Specialized Training for Transfer of Knowledge (ToK). Swiftships’ approach is highly flexible and tailored to our customers’ needs. We offer our clients different packages based on their objectives and requirements. They may vary from vessel’s design licensing, to full scope assistance in developing production capability, KITs supply and day-to-day management, and early stage of planning yard support and operations.

Swiftships collaboration with Egyptian Navy and USN is an industry exemplary case. We provided Planning Yard and Sustainment Site services for Egyptian Navy in Alexandria, and trained local labor. Since 2006, over 25 vessels were co-produced, and additional 16 are under active contract. During the program, Egypt constructed vessels from U.S. procured material employing in-country labor under Swiftships Subject Matter Expert (SME) support and QA guidelines from ABS.

Case Studies:

Subsegments and Services:

Swiftships offers to its client various Training programs and Integrated Logistics Support services as part of contracts or as a standalone solutions.