Co-production/

technical cooperation

Comprehensive Support in Establishing Local Capabilities

For economic and strategic reasons, our clients may choose to have vessels constructed at their locations. Swiftships recognized these needs, and became a U.S. based maritime company specializing in global co-production programs. Our localization programs support governments in increasing their indigenous industrial base, creating local employment and bringing technology and know-how to their countries for long-term benefits.

We have extensive experience working with international clients, and we are very familiar with ITAR (International Traffic in Arms Regulations) requirements and processes for Transfer of Technology (ToT), Transfer of Production (ToP), Program Management (PM) and Specialized Training for Transfer of Knowledge (ToK).

Build-Operate-Transfer and Manage (BOTM)

Swiftships’ approach is highly flexible and tailored to our customers’ needs. We offer our clients different packages based on their objectives and requirements. They may vary from vessel’s design licensing to full scope assistance in developing production capability, KITs supply and day-to-day management. Our scope of expertise spans across the following areas:

- Feasibility Study and Project Planning for Local Production

- Maritime Infrastructure Planning, Design and Development

- Planning Yard

- Design Royalty/Licensing and Transfer of Technology (ToT)

- Transfer of Knowledge (ToK) and Data Packages

- Production Readiness

- Transfer of Specialty Equipment and Systems

- Agreement Implementation under DCS or FMS, and other Documentation

- Supply Chain Planning, Implementation and Management Systems

- Specialized Training Programs

- R&D and Innovation Capability Development

Designs and Technology Licensing, and Production Readiness

Comprehensive Training Programs

Swiftships has developed the best practices for knowledge transfer through specialized training programs for management and workforce, including:

- USA-based Shipbuilding and Kit Assembly Training

- Hands-on Co-production Support at the Client’s Location

- In-classroom Instructor-led Training

- On-the-job Mentoring and Micro-learning

- Simulator-based Training

- Fleet Operations and Maintenance

Program Management

Our program management scope includes program feasibility study, planning, implementation and day-to-day management. Our methods are focused on knowledge and technology transfer to develop local production capability in the most efficient way and to roll-out local production successfully. We provide a comprehensive planning of the entire program and ensure full execution in the agreed time frame.

Swiftships provides clients a comprehensive list of international suppliers. We help our clients evaluate and select the optimal providers, build sustainable supply chain, efficient inventory management system and manufacturing process systems.

Customer Benefits

We work closely with our clients during the localization program. We provide swift solutions to any possible challenge that might arise and ensure our customers reach their goals.

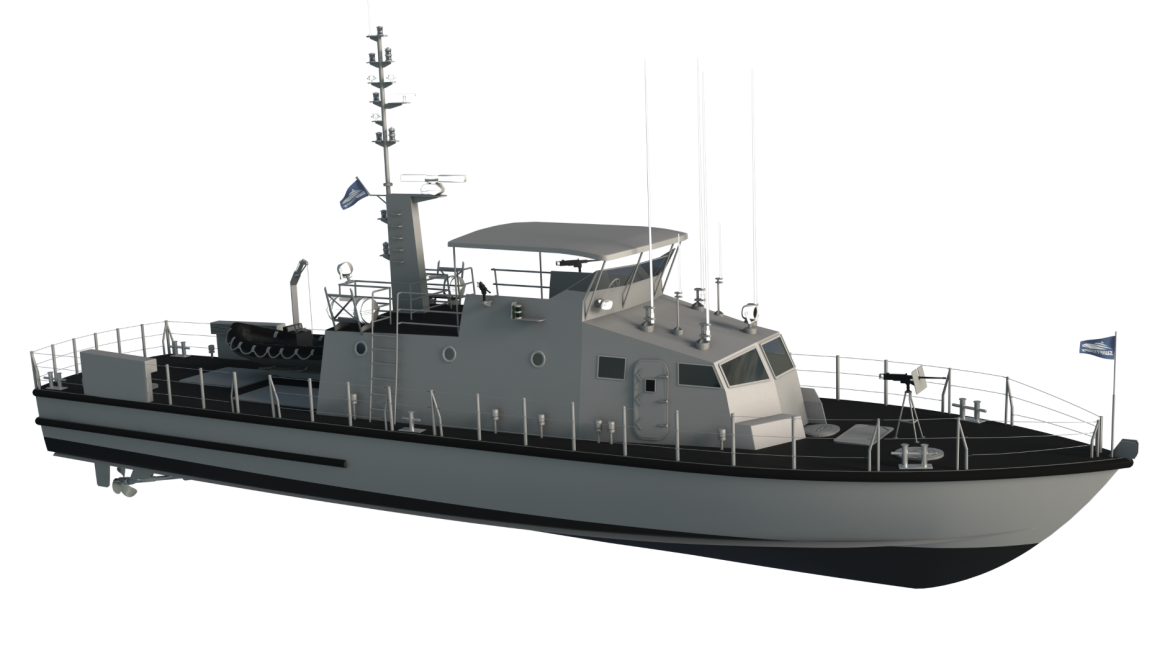

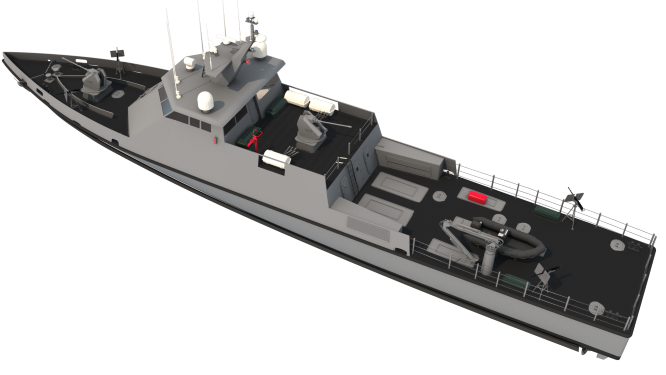

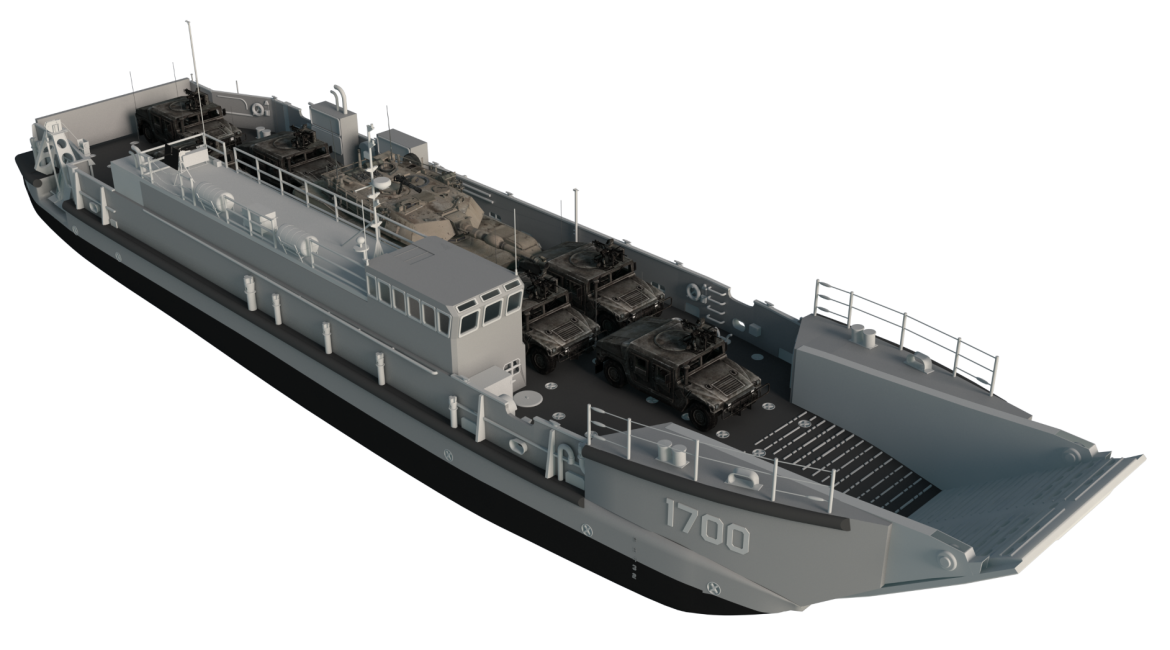

- Access to over 100 proprietary designs and hulls for military and commercial vessels

- Turnkey production readiness for all phases of construction for vessels of all sizes—small (Riverine Craft to FPVs), medium (OPVs to Corvettes), and large (Frigates and Multi-Mission Surface Combatants)

- Access to various suppliers and partners to address complex elements such as systems integration, design-engineering, training, and operation

- Personal assistance in obtaining approval under International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR) approval processes

- Opportunity to achieve optimal shipbuilding capacity and ship-operation lifecycle support (warranty and follow-on-technical support)

- Access to Swiftships’ continuous R&D development and innovation

- Continuous training programs