Swiftships

Awards

Case Study

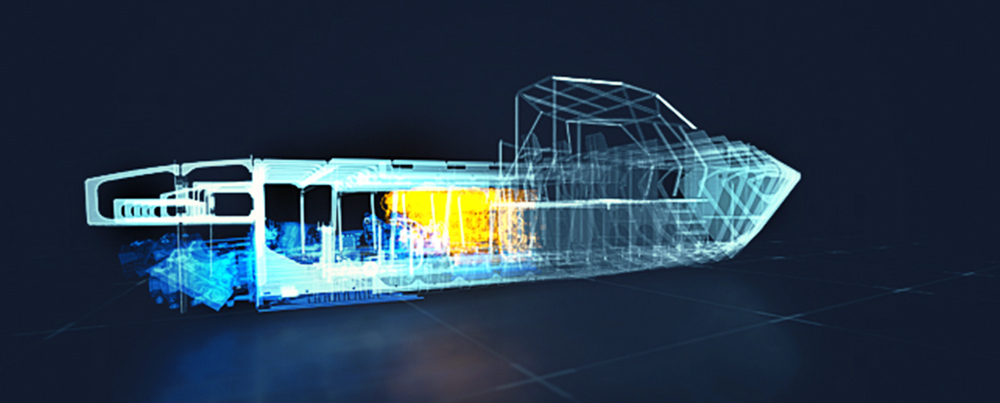

Swiftships Supply of Kit of Material (KoM) for In-country Co-Production using Indigenous Labor

Swiftships’ relationship with the Egyptian Navy (EN) started in the earlier nineties, where it delivered two (2) 54m Missile Retrievers and Eight (8) 28m Coastal Patrol Crafts (CPC) under a Direct Commercial Sales (DCS) contract. In 2006, Swiftships further delivered Six (6) 26m Fast Patrol Crafts (FPC) and later in 2009, Swiftships delivered two (2) 28m CPC and co-produced Four (4) initial Kit of Material, which were built in Egypt under Swiftships QA and guidance. Based on mutual trust and exemplary performance during the project execution, USN was directed by EN to sole-source through a Foreign Military Sales (FMS) contract to deliver additional 26m and 28m CPCs.

Scope: Planning Yard and Sustainment Site for Egyptian Navy in Alexandria, Egypt to construct US procured material using in-country labor under Swiftships Subject Matter Expert (SME) support and QA guidelines from ABS.

Planning Yard: Swiftships’ work started with the planning yard initiative. We prepared complete feasibility studies and execution plans. Swiftships assisted in building, modernizing, and furnishing over 5.5 acres of office space, five production bays, two syncrolifts, and a dry port, enabling the Egyptian Shipyard to build steel and aluminum vessels and repair ships of up to 70 meters. Its features are a mechanical slipway, floating dock and cranes, and advanced paint systems.

Transfer of Knowledge and Production (ToK/ToP): Swiftships team provided On-Job Training (OJT) under joint approval from US Navy DSCA/Pol-Mil Bureau and DoS under a Manufacturing Liscence Agreement (MLA). Our ToK/ToP methods effectiveness reflected in the Egyptian team’s ability to produce ships with the same quality and performance as those built-in Swiftships’ in the US yard.

Continuity: Swiftships-EN relationship progresses, and the EN is pursuing several expansion plans from 28m to 35m, and other designs are being discussed. EN and Swiftships started co-market 28m CPCs for other the Middle East and African Navies, whereas the Swiftships would support EN in building the vessels in EN industrial-base.

Approach: We delivered raw material and kits under our ToP program and provided Subject Matter Experts (SMEs) in-country support for the EN. We offered a WH and Supply Chain system, licensing, documentation and integrated logistics services to enable the EN success on the co-production program. The local Egyptian workforce assembled an integrated approach to building the 28m CPCs.

Results: By combining FMS and DCS contracts, Swiftships has co-produced Twenty-six (26) 28m CPCs by 2021 under the US Navy’s High-Speed Naval Craft (HSNC) rules at the Egyptian Shipyard. EN has further contracted Swiftships for Sixteen (16) 28m CPCs to be co-produced by 2023 with options/total requirement for up to Fifty (50) excluding other African navies requirements.

Vessels Co-produced and Built by the Egyptian Shipyard