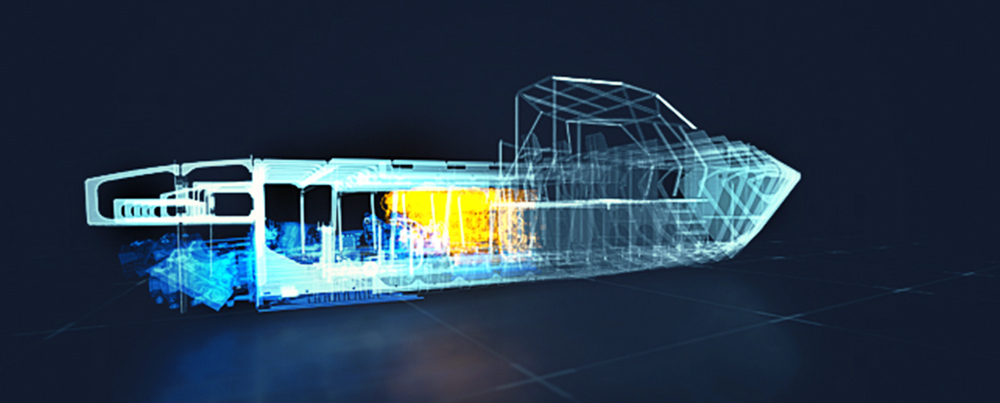

Service life extension

Reducing Maintenance Cost and Risks

Swiftships Service Life Extension Program (SLEP) describes an extension or upgrade of an asset of the US government, usually of the U.S. military. Swiftships coordinates directly with USG, the Program Office, the Engineering departments, the Defense Logistics Agency (DLA), and several agencies to administer comprehensive task orders to avoid replacement costs and reduce vessel’s downtime.

Our custom SLEP effort enables our client’s participants to provide adequate oversight, ensure effective inventory controls, and monitor stockpiles for shelf life extension opportunities. The program also enables us to develop and implement more efficient stockpile replenishment plans for the future. The intended outcome of the SLEP is measurable cost avoidance returned to program participants and continued availability of potency-dated contingency stocks.

Our standard processes is described as:

- the USG acts as the single interface between the program participants who submit a product for testing

- the program participants funds the “Scope” of the program and receive the benefit of deferred material replacement costs on a cost-plus-fee (CPF) model

- the USG conducts potency to extend product life

Service Approach

• Use of U.S. Navy-approved techniques to determine deficiencies

• Testing all mechanical systems, including engines, generators, auditing engine hours records

• Testing oil samples

• Testing electrical systems

• Hull and superstructure inspections, strength assessment including measurement of plate thickness and load testing of lifting and mooring points

• Documentation and photography to record observed deficiencies

• Assessment report and scope-of-work definition

• Agreement on Scope of Work

• Detailed budgeting

• Material and Equipment List

• Selection of Supplies, vendors, and sub-contractors

• Logistics plan

• Project management procedures and reporting routines

• Quality management plan

• Agreement on testing and trial criteria

• Swiftships develops its major overhaul repair work packages according to the Docking Selected Restricted Availability (DSRA) regulation

• Reporting any unplanned/unforeseen repairs required. Swiftships tracks the platform’s material condition during overhaul and identifies any work needed outside of the approved work package. In addition, Swiftships conducts diagnostic efforts to determine the extent of damage, and generates a preliminary list of required parts and tools, prior to emergent work repair

• Swiftships corrects all platform deficiencies to restore ships to the original state condition, prior to equipment malfunction or failure

• All tasks such as including identifying, planning, scheduling, managing, and documenting work repair, are completed in accordance with applicable systems and original equipment manufacturer (OEM) procedures

• Under-way (sea) trials

• Post-sea trials

• Test result reporting, and any deficiencies to be corrected. And test repeated, in case required

• Customer’s acceptance

Case Study

SLEP for the US Army Landing Craft Utilities (LCUs)

Swiftships executed a major program for the U.S. Army on SLEP for LCU 2000 vessels. The scope included:

- On-Condition Cyclical Maintenance (OCCM)

- Replacement of propulsion engines and bow thruster engines

- Replacement of generators including emergency generator

- Replacement of electrical switchboard

- Condition-based hull and superstructure repairs

- Replacement of selected communication and navigation systems

As the initial effort, Swiftships Systems Engineering and Production team provided amplifying information about the continued use of the US Army’s LCU 2000 vessels. We completed Service Life Extension Assessment (SLEA) and determined the risks and the life cycle costs of continuing the product or service versus the cost of a replacement system. The program involved three (3) LCU’s, each with different design variations.

Our SLEP program concluded the following:

- a cost plan of SLEP operation was submitted to the US Army per vessel

- a maintenance plan was submitted with a schedule, and cost (if criteria exceeded the cost, additional funding was requested via CFRs)

- upon further inspection during the effort, if parts/systems were about to reach their operations life limits, an On-Condition Cyclical Maintenance (OCCM) plan was submitted per task for further approval

- if parts/systems were no longer available for repair and maintenance, an alternative (Boat ALT) was submitted to the Army Watercraft Division for Engineering approval

Swiftships System Engineers and Logisticians proactive approach to predict, led to tremendous savings and minimum vessels downtime. Our proven SLEP methodology allowed to prevent system failures before the operations and support costs rise above acceptable limits.

In addition, our PMO team tracked critical factors during the entire SLEP effort:

- Current life cycle costs of the system

- Design life and expected remaining useful life of the system

- Software maintenance

- Configuration management

- Warranty policy

- Availability of parts, subsystems, and manufacturing sources

- Availability of system documentation to support life extension